Full Chain Competence and Capability

Carbon Circle's Scope of Services includes all phases from concept screening throughout all project phases including commissioning, start-up and operational services.

Our competency spans from flue gas treatment and carbon capture, through CO2 Conditioning and Handling to Balance of Plant, Heat Integration and Utility Systems. This means that we are able to take on a holistic view and deliver Full Chain projects within CCS.

Our Project Execution Philosophy is simple. We have key personnel competence in-house and depend on close operation with strategic partners. For early phase work we normally assumes overall responsibility for CCS projects and draws on partners and suppliers on a case-by-case basis. For later phase work, we normally team up with an EPC partner, enabling full EPC wrapping including all work related to on-site installation, construction, MC, commissioning and start-up.

Advisory - CCS chain

Practical, independent advice across the full CCS value chain - from source characterisation and capture selection to CO₂ conditioning, transport, and storage. We focus on clear decisions, robust interfaces, and regulatory compliance.

What we cover

- Source & capture: Flue-gas profiling, capture route screening, indicative performance/energy.

- CO₂ conditioning: Dehydration, compression, impurity control, export specifications.

- Transport options: Pipeline vs. ship assessments, logistics, intermediate storage/buffer needs.

- Storage & offtake: Screening of sites/offtakers, deliverability, contract structures.

- MRV & permitting: Emissions monitoring strategy, approvals path, conformity with ETS rules.

- Commercial & risk: Cost ranges (CAPEX/OPEX), incentives/funding, risk allocation.

- Delivery planning: Execution models, procurement approach, Owner’s Engineer/independent reviews.

Concept and Feasibility Studies

We turn early-stage questions into clear, decision-ready options. Our team assesses technical fit, site integration, cost, schedule, and risk - for any part of the CO₂ chain.

Typical scope and deliverables are:

- Site-specific capture concept: plot/lay-out, tie-ins, utilities, emissions strategy.

- Performance & energy: mass/heat balance, SRD (kWh/t CO₂), heat integration options, CO₂ specifications, CO₂ conditioning/transport alternatives.

- Cost & schedule: Class 4/5 CAPEX/OPEX, delivery timeline, high-level execution plan.

- Decision package: go/no-go and a clear scope for pre-FEED/FEED.

FEED

FEED (Front-End Engineering Design)

We turn your selected concept into an EPC-ready design with locked scope, cost and schedule. Built on our open CESAR1 platform and pre-engineered CaCiMod modules, our FEED is fast, predictable, and de-risked for execution.

Typical scope and deliverables are:

- Scope & basis locked: Design basis, battery limits, PFDs/HMB, control philosophy, HAZID/HAZOP close-out.

- 3D layout: Plot plan, modules breakdown, lifting/transport studies, constructability and site logistics.

- Equipment & vendors: Specs, inquiry packages, bid evaluations, preferred vendors and budget quotes.

- Integration & compliance: Utility/tie-ins, heat integration, CO₂ conditioning & export spec compliance design, CEMS/AMS concept, permitting dossier.

- Cost & schedule: Class-3 CAPEX/OPEX, L2/L3 schedule, execution & procurement strategy, risk/contingency, commissioning & performance test outline

EPC

EPC (Engineering, Procurement & Construction)

Together with our partners, we deliver your capture plant from design to first CO₂. With single-point accountability and an EPC wrap, we execute using our CaCiMod modules and open CESAR1 platform for predictable cost, time, and quality.

Typical format and deliverables::

- Single contract, clear risk: EPC option with governance, change control, and contingency management.

- Detailed engineering & procurement: packages, vendor selection, expediting, QA/QC, FAT/SAT.

- Modular fabrication & logistics: Shop-built modules, factory testing, transport and lifting plans.

- Completions & commissioning: MC/SC, system turnover, pre-comm, dynamic commissioning, start-up.

- Performance & compliance: Guaranteed capacity/SRD/emissions

- Operations readiness: O&M manuals, training, spare parts, ramp-up support.

Operational Services

Capture Technologies

Modular Carbon Capture - CaCiMod

Oslo

Headquarters

Strandveien 15, 1366 Lysaker, Norway

Aberdeen

UK Office

119 Grandholm Drive, Aberdeen AB22 8AE, UK

Europe and North America

Key Markets

Customer segments

Carbon Circle provides specialized solutions tailored to various industries, addressing unique needs and challenges in carbon capture and energy transition.

Carbon Capture Systems

Carbon Circle designs modular and standardized carbon capture plants, acting as a turnkey EPC contractor for both offshore and onshore clients, with a focus on mid-sized projects.

Energy-from-Waste (EfW)

We offer EPC contracts for EfW plants, handle subcontracting for EfW engineering work, and integrate carbon capture systems into EfW plants.

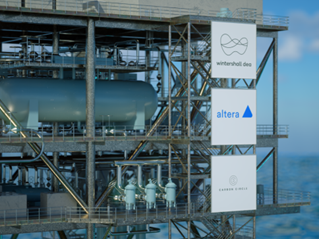

Offshore oil & gas topside

In the offshore oil and gas sector, we execute EPC for topside integration and modifications, subcontract detailed engineering, and integrate carbon capture solutions.

Get in touch

Ready to start your CCS journey or eager to learn more about Carbon Circle's offerings? Reach out to us, and we'll get back to you promptly.