Modular Carbon Capture,

Ready in 21 Months

Leveraging Carbon Circle's in-house modularization experience with our carbon capture expertise, we have developed the carbon capture process into a complete capture plant design, with a strong focus on energy efficiency, operational reliability, footprint and cost-effectiveness. The design is fully modularised, enabling streamlined fabrication, reduced on-site installation time, and scalable deployment across various industrial applications.

We call it our CaCiMod family

CaCiMod turns full-scale CO₂ capture into factory-built, road-transportable skids. Standardised design cuts CAPEX, footprint and delivery time - ideal for retrofits and space-constrained sites.

The intention is to enable offering of pre-engineered modular solution for several capture capacities. Our design philosophy is based on project specific optimization, within standardized modular sizes of given CO2 capacity ranges. All models incorporate optimized amine-based capture technology simulations and are designed with focus on low energy consumption and minimal emissions.

Proven Technology

CaCiMod uses the open-source CESAR1 amine blend, vetted through 40 000 + operating hours at sites like Mongstad and Norcem Brevik.

No licence fees, no proprietary chemistry—just transparent performance data regulators already trust.

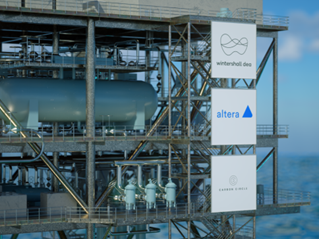

Combined with Carbon Circle’s 30-engineer EPC team (first offshore post-combustion CCS unit in 2024), it’s a low-risk path to large-scale capture.

Get in touch

Ready to start your CCS journey or eager to learn more about Carbon Circle's offerings? Reach out to us, and we'll get back to you promptly.